2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

Tower Dry-Mix Mortar Mixing Plant

NFLG FBT4500 tower-type dry mortar mixing plant is applied to Jiangsu, China

- Location: Jiangsu, China

- Model: FBT4500

- Startup: 2019

- Equipment highlights: Intelligent and efficient, accurate measurement, safety and energy saving

Tower Dry-Mix Mortar Mixing Plant

Introduction& Advantages

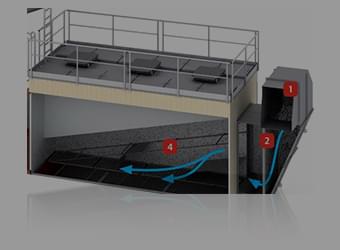

NFLG tower-type dry mortar mixing plant is arranged from top to bottom according to the production process, and the production is relatively smooth. It is suitable for the production of ordinary mortar and various special mortar, with many kinds of products and small cross pollution of raw materials. It has small floor area, atmospheric appearance, relatively low energy consumption, and relatively large initial investment compared with other process structures.

- Tower structure, without secondary lifting and conveying, the mixing system can reduce consumption by about 25%. the mixing efficiency is about 30% higher than that of the traditional double-horizontal shaft mixer.

- When the equipment is in operation, the dust emission concentration<20mg/ Nm³ (optionally<10mg/Nm³ configuration), and the noise at boundary<55dB.

Parameters

| Model | FBT1200 | FBT2000 | FBT3000 | FBT4500 | FBT6000 | note |

|---|---|---|---|---|---|---|

| capacity(t/h) | 10~20 | 20~40 | 40~60 | 60~80 | 80~120 | |

| main machine | FJD1200 | FJD2000 | FJD3000 | FJD4500 | FJD6000 | |

| power(kW) | 30 | 37 | 55 | 75 | 110 | |

| high speed end | two-pole (7.5kW)、four-pole(5.5kW)(optional) | two-pole (7.5kW)、four-pole(5.5kW)(optional) | two-pole (7.5kW)、four-pole(5.5kW)(optional) | two-pole (7.5kW)、four-pole(5.5kW)(optional) | two-pole (7.5kW)、four-pole(5.5kW)(optional) | |

| volume fraction of mixer | 70% | 70% | 70% | 70% | 70% | |

| aggregate size (mm) | 0~4.75 | 0~4.75 | 0~4.75 | 0~4.75 | 0~4.75 | |

| aggregate scale(kg) | (200~1300)±1% | (200~2000)±1% | (400~3000)±1% | (400~3800)±1% | (500-5800)±1% | adjustable according to client’s requirement |

| cement scale(kg) | (100~700)±1% | (100~800)±1% | (200~1300)±1% | (200~1800)±1% | (200~2000)±1% | adjustable according to client’s requirement |

| additive scale(kg) | (5~30)±0.5% | (10~50)±0.5% | (10~200)±0.5% | (10~200)±0.5% | (10~200)±0.5% | adjustable according to client’s requirement |

Drying system

the double-return drying drum, intelligent monitoring and easy maintenanceThe two-layer drying drum is used to avoid the additives failure due to excessive sand temperature. The system also provides the unique intelligent detection, the online warning system, the fault indication function, and the humanized control interface.

Screening system

stable and efficient, automatic cleaningThe efficient and stable probability screen provides the screening efficiency greater than 85%.It is convenient for fine production, high efficient, self-cleaning screen system, free of maintenance.

Dust removal system

intelligent cleaning, energy saving and environmental protectionThe system uses the unique integrated container (gravity + bag) dust collector to achieve intelligent control of pulse ash removal, with the all environmental emissions less than 20mg/Nm³.

Weighing system

accurate and stable, quality controllableDesigned with unique VF feeding technologies to realize batching accuracy higher than requirements of industrial standards.

Mixing system

high efficiency, energy saving, wear resistance and loss preventionNFLG combines advanced plow type mixer, patented core technology and unique VF patented mixing technology to ensure high efficiency and energy saving by 25%, maximum mixing ratio: 1:10000, high wear resistance and long service life.

Packaging system

high automation efficiency, cost savingWith the design of a complete set of automatic packaging palletizing and packaging production lines, no worry about the production of large-scale special mortars; it is equipped with multi-model packaging machines and is an all-rounder for different mortar packaging.

Bulk system

prevent mortar separation, ensure energy conservation and environmental protectionThe bulk system of NFLG can effectively prevent the separation of finished mortar during loading, improve loading efficiency, reduce energy consumption, ensure the site environment and meet the environmental requirements.

Full environmental protection bulk dust collecting system

fast dust collecting, better effectThe unique bulk unloading and dust collection separation control optimizes dust removal efficiency, which is the best technology in the industry.

Demand customization

varies according to needsProvide scientific customization services, according to the actual needs of the project, it can be equipped with a centralized system of environmentally friendly clean chemical plants, non-standard requirements of special mortar production lines, automatic palletizing systems, etc.